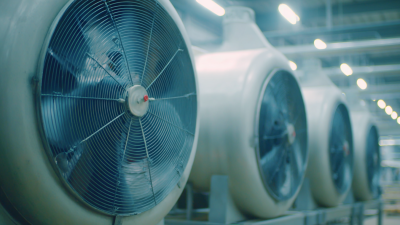

Centrifugal fans play a critical role in various industrial applications, providing efficient air movement for ventilation, cooling, and exhaust systems. As businesses increasingly focus on energy efficiency and sustainable practices, the demand for high-performance centrifugal fans continues to grow. According to a report by Research and Markets, the global centrifugal fan market is projected to reach USD 7.8 billion by 2025, driven by advancements in fan technology and rising industrialization in emerging economies.

In selecting the best centrifugal fan for your needs, it is essential to consider factors such as airflow capacity, pressure requirements, energy consumption, and noise level. The significance of these factors cannot be overlooked, as they directly impact operational efficiency and overall system performance. Moreover, with the increasing emphasis on green technology, modern centrifugal fans are being designed to minimize energy usage while maximizing output, thus playing a pivotal role in sustainable industrial operations.

This ultimate guide aims to provide a comprehensive overview of the top 10 centrifugal fans for 2025, helping you navigate the myriad options available in the market. By understanding the essential features and benefits of each fan, you can make informed decisions and optimize the performance of your ventilation systems.

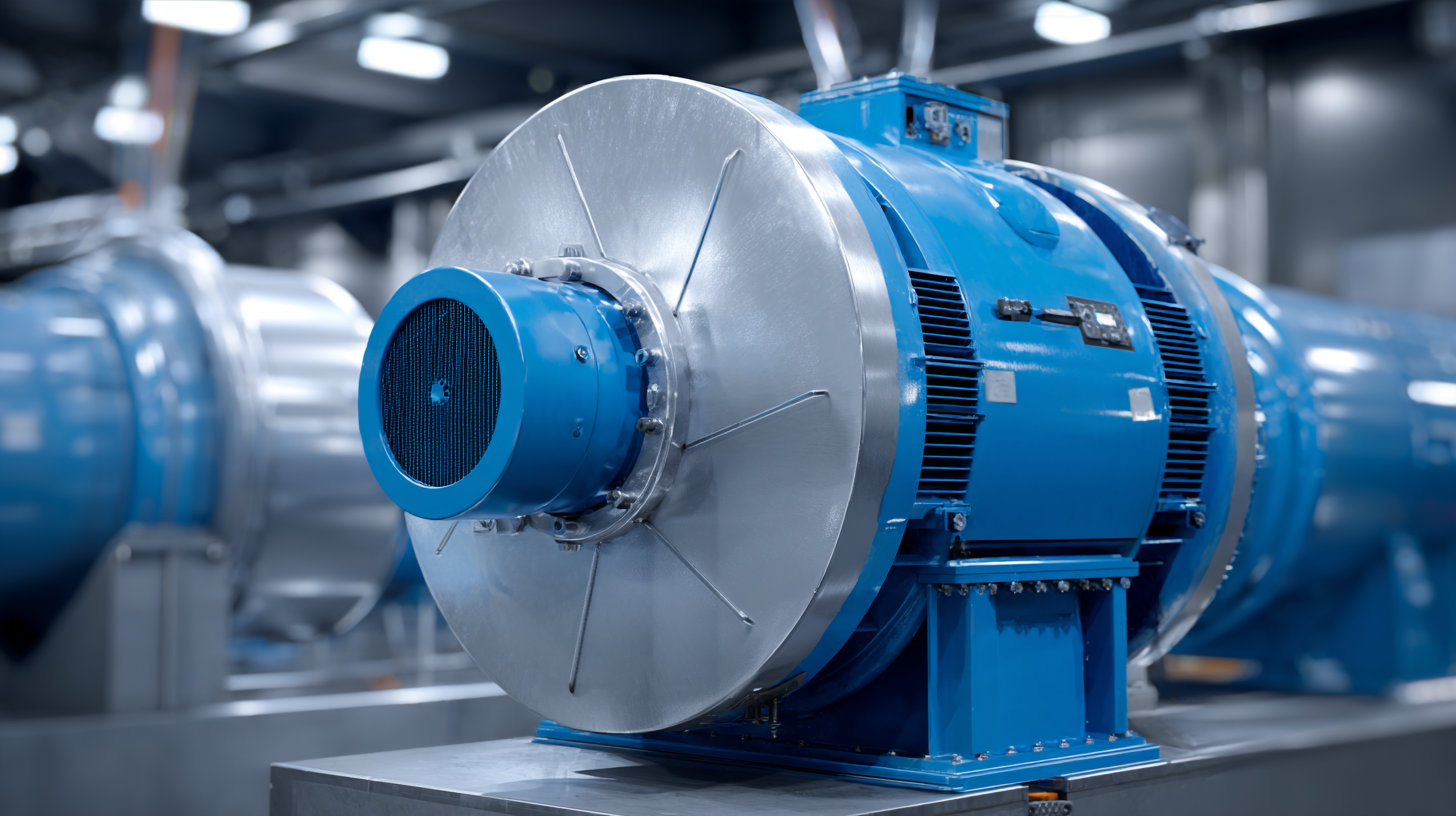

When selecting a centrifugal fan in 2025, several critical features should guide your decision-making process. First and foremost, consider the fan's airflow performance, measured in cubic feet per minute (CFM). A fan with a higher CFM rating will efficiently move larger volumes of air, making it better suited for industrial applications or larger spaces. Additionally, ensure that the fan is equipped with adjustable speed settings, allowing for tailored airflow based on specific requirements.

Another essential feature is the fan's energy efficiency. Look for models that comply with the latest energy standards, as this will not only reduce operational costs but also have a positive environmental impact. Material quality is also crucial; fans made from durable materials such as galvanized steel or high-grade plastic can withstand harsh conditions, leading to increased longevity and less frequent replacements.

Tips: When evaluating options, check for noise levels listed in decibels (dB). A lower dB level indicates a quieter operation, which is especially important for residential or noise-sensitive environments. Consulting customer reviews can also provide insights into long-term performance and reliability of the fan models you are considering. Finally, don’t overlook warranties and customer support, as these can offer peace of mind in case of future issues.

When selecting a centrifugal fan, understanding performance metrics is crucial for ensuring you choose an efficient and effective model. Fan efficiency is typically measured as the ratio of the useful power output to the total power input, often expressed in percentage. Higher efficiency figures indicate that more of the input power is being converted into airflow, minimizing energy wastage. It's essential to compare efficiency ratings among different fans, especially if operating costs are a concern, as an energy-efficient fan can lead to significant savings over its lifespan.

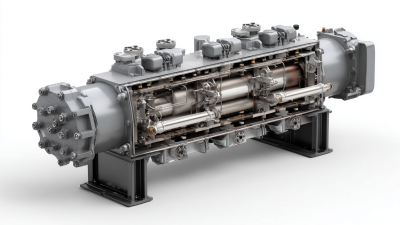

Power ratings, on the other hand, provide insights into the maximum output a fan can achieve, typically measured in horsepower or watts. This metric is vital when assessing whether a particular model can meet the specific airflow and pressure requirements of your application. Understanding the relationship between power and airflow allows users to better match a fan's capabilities to their operational needs, ensuring optimal performance. When making a decision, consider both these metrics together for a comprehensive understanding of a fan's performance potential.

When selecting centrifugal fans, material choice plays a crucial role in both durability and performance. Common materials for fan construction include steel, plastic, and aluminum, each offering distinct advantages and drawbacks.

Steel fans are renowned for their strength and resistance to wear and tear, making them ideal for heavy-duty applications. However, their weight can be a disadvantage in situations where lighter fans are preferred for easier installation and less stress on mounting structures.

On the other hand, plastic fans provide a lighter alternative that is highly resistant to corrosion, making them suitable for environments where moisture is a concern. They are typically used in applications that do not require the robustness of metal fans but still demand a reliable and efficient performance.

Aluminum, known for its balance of weight and strength, offers exceptional durability while remaining lightweight, making it a versatile choice for various fan designs. When choosing the best centrifugal fan, considering the specific material properties in relation to the intended application will ensure optimal efficiency and longevity.

When choosing a centrifugal fan, one paramount factor to consider is noise levels, measured in decibels (dB). Most industrial fans operate between 60 and 90 dB, but even small variations can make a significant difference in a work environment. According to a report by the American Noise Control Association, prolonged exposure to noise levels above 85 dB can lead to hearing impairment and increased stress levels, making it crucial to select fans that align with the noise regulations in your industry.

To minimize noise impact, consider fans designed with sound-dampening features. Many manufacturers provide specifications regarding the sound power level and the placement of fans can further influence noise pollution. Installation location, such as placing fans on vibration-absorbing mounts or in sound-insulated housings, can reduce transmitted noise significantly.

Tips: Always check the fan's dB rating in different operating conditions to understand how it might perform in your setting. Opt for models with variable speed drives, as they allow for noise reduction during lower operation needs. Additionally, consult the fan's certification for noise standards, ensuring compliance with regulations like ISO 3744 for testing methods.

This chart displays the noise levels of the top 10 centrifugal fans in decibels (dB). The recorded noise levels range from 42 dB to 60 dB, providing insights into how different models compare in terms of sound output. Lower dB values indicate quieter operation, which is critical for applications where noise is a concern.

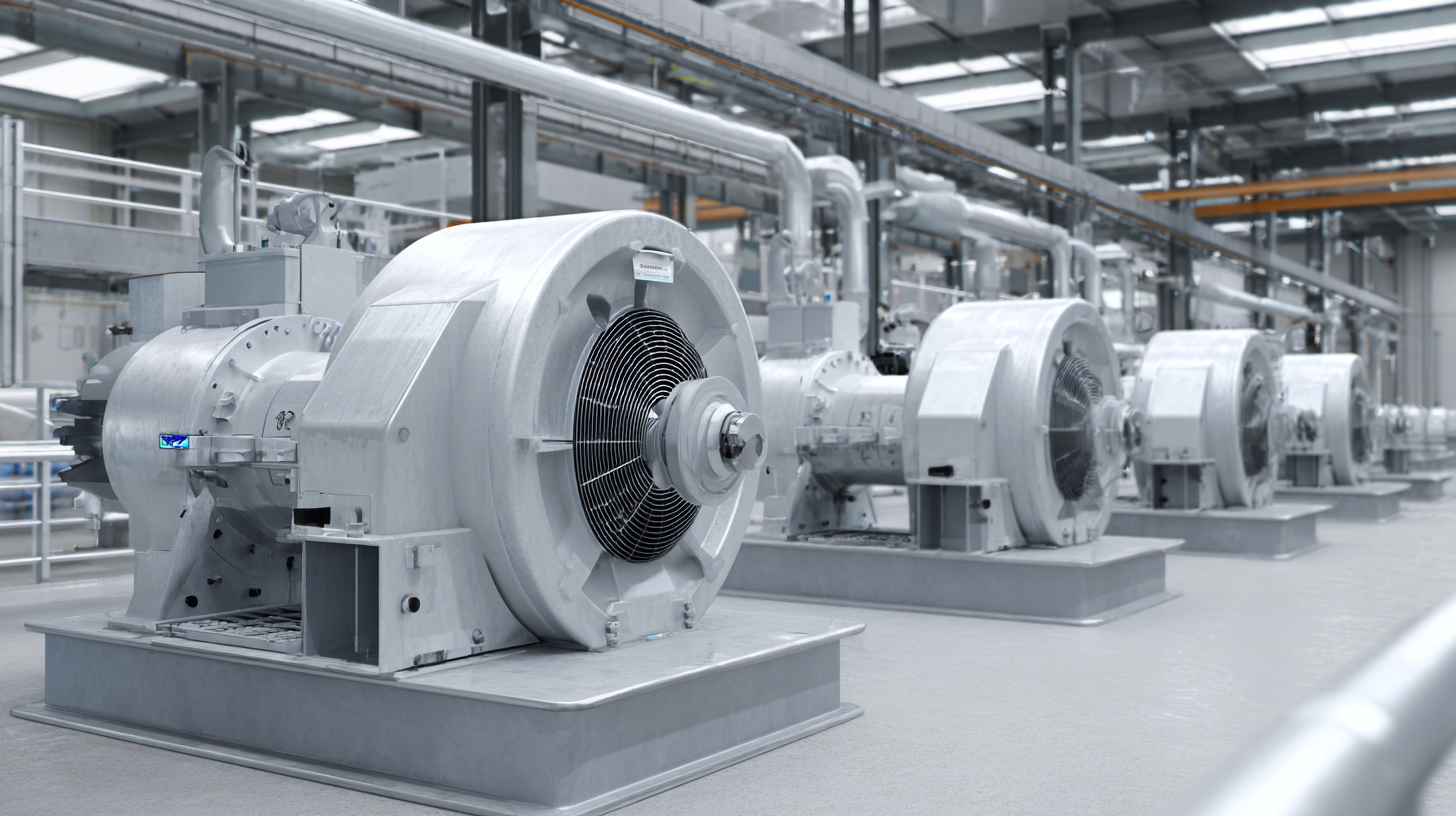

In 2025, the centrifugal fan market is set to showcase remarkable advancements, with several leading manufacturers competing for the top spot. A comparative analysis of the best models reveals varying features, efficiencies, and innovations that cater to a diverse range of industrial applications. Performance metrics, such as airflow capacity and energy consumption, are pivotal when assessing which fans offer the best value. The top brands are integrating cutting-edge technologies to enhance durability and minimize noise levels, positioning themselves as frontrunners in sustainable design.

As the demand for high-performance equipment grows, understanding the nuances of each model will help consumers make informed decisions. Factors like the material used, ease of maintenance, and customer support services play a significant role in the overall user experience. Additionally, the evolution of smart technology in centrifugal fans promises to elevate user convenience and operational efficiency, making it essential for businesses to stay attuned to market trends in order to adopt the most suitable solutions for their needs. Whether for HVAC systems or manufacturing processes, the right centrifugal fan can significantly impact performance outcomes.