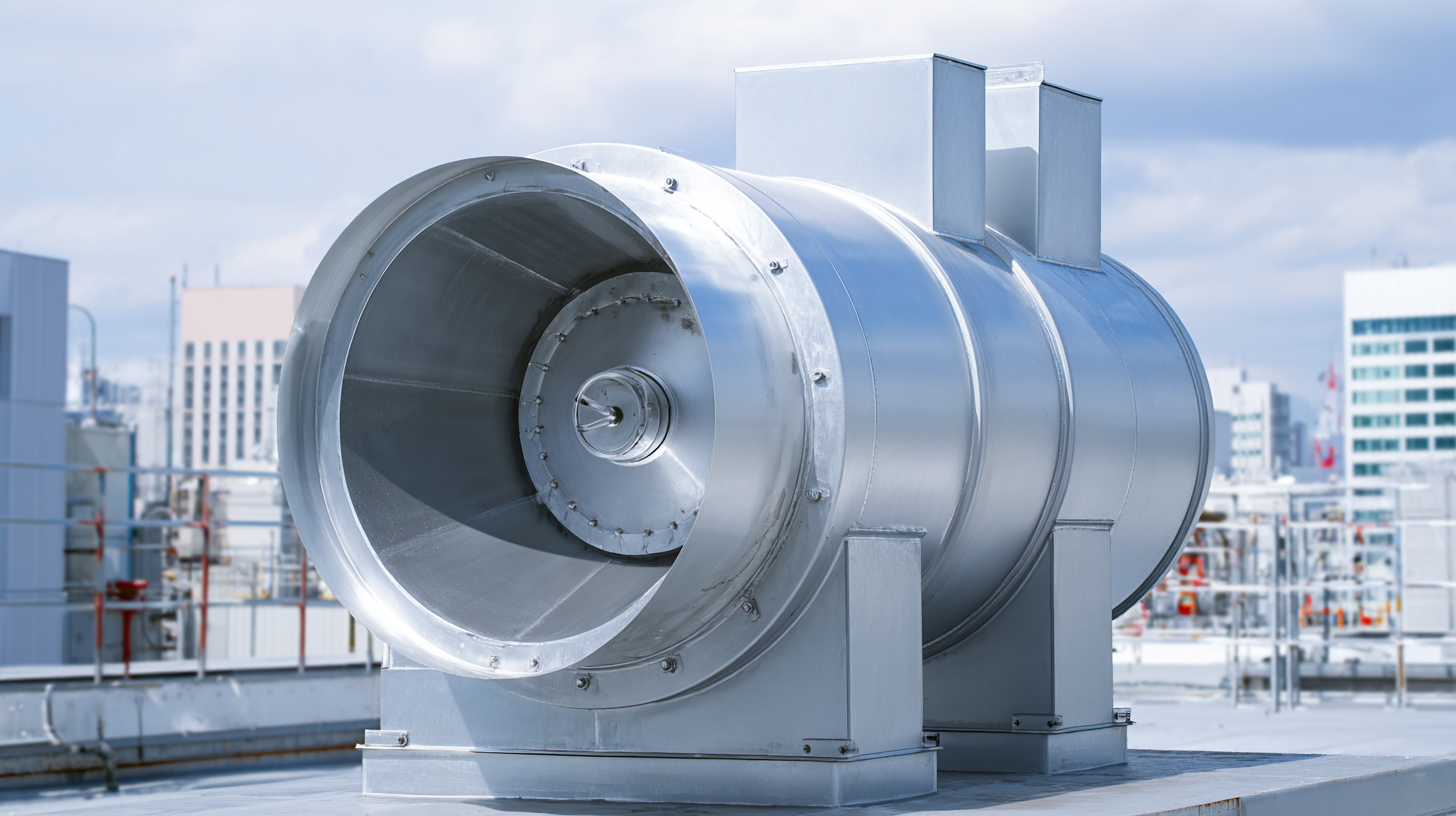

In modern ventilation systems, the importance of effective air circulation cannot be overstated, particularly in industrial and commercial settings where air quality and temperature control are crucial. One of the key components in achieving efficient ventilation is the Centrifugal Exhaust Fan. This type of fan plays a vital role in expelling stale air and regulating environmental conditions within a space, ensuring that the indoor atmosphere remains healthy and conducive for various activities. With their unique design, centrifugal exhaust fans can handle large volumes of air and provide a high static pressure, making them ideal for challenging applications such as those found in factories, kitchens, and other confined areas. This article will delve into the numerous benefits and applications of centrifugal exhaust fans, highlighting their integral role in enhancing the performance of contemporary ventilation systems.

Centrifugal exhaust fans play a crucial role in enhancing indoor air quality by efficiently removing stale air, odors, and pollutants from enclosed spaces. Their design allows for high airflow rates and static pressure, making them ideal for environments where strong ventilation is necessary, such as kitchens, laboratories, and industrial settings. By ensuring a continuous flow of fresh air, these fans help mitigate the buildup of harmful contaminants, thus promoting a healthier indoor atmosphere.

Moreover, centrifugal exhaust fans contribute to humidity control within buildings. Excess moisture can lead to mold growth, which poses significant health risks. By actively expelling humid air, these fans assist in maintaining optimal humidity levels, thereby preserving both structural integrity and occupant well-being. Their versatility and effectiveness make them a key component in modern ventilation strategies, underscoring their importance in safeguarding indoor air quality across various applications.

Centrifugal exhaust fans play a crucial role in various industries, providing efficient ventilation solutions tailored to specific needs. In commercial kitchens, for instance, these fans are instrumental in removing smoke, heat, and odors, thus ensuring a safe and comfortable working environment. Their ability to handle high airflows with low noise levels makes them an ideal choice for food preparation areas, where maintaining air quality is vital to both health and food safety.

In the manufacturing sector, centrifugal exhaust fans are essential for controlling indoor air quality by expelling harmful fumes and particulate matter generated during production processes. Industries such as automotive, chemical, and textile frequently utilize these fans to meet stringent regulatory requirements for air purity. Furthermore, they are employed in HVAC applications to enhance the circulation of conditioned air throughout large facilities, ensuring energy efficiency and optimal thermal comfort for occupants. The versatility of centrifugal exhaust fans makes them indispensable across a range of industrial settings, highlighting their importance in modern ventilation systems.

When selecting centrifugal exhaust fans for modern ventilation systems, several key features should be prioritized to ensure optimal performance and efficiency. The first important aspect is the fan’s airflow capacity, measured in cubic feet per minute (CFM). This measurement indicates how effectively the fan can remove air from a space, which is critical in maintaining indoor air quality. Ensure the chosen fan can handle the specific airflow requirements of your application.

Another vital consideration is noise level, which is often measured in decibels (dB). Some applications, particularly in residential or sensitive environments, require quiet operation. Look for fans designed with noise reduction features such as insulated casings or specially engineered impellers that minimize sound while delivering efficient airflow.

**Tips:** Always consult the manufacturer’s specifications to match the fan’s capabilities with your needs. Additionally, consider energy efficiency ratings; models with higher efficiency can lead to significant cost savings over time. Finally, ensure that the fan is easy to install and maintain, which can save you time and hassle down the road.

Centrifugal exhaust fans play a crucial role in enhancing energy efficiency within modern ventilation systems. According to industry reports from the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), the implementation of energy-efficient centrifugal fans can reduce energy consumption by up to 40% compared to traditional axial fans. This significant reduction in energy use not only lowers operational costs but also minimizes the carbon footprint of commercial and industrial facilities, contributing to sustainability goals.

The cost savings associated with centrifugal exhaust fans extend beyond energy consumption. A study by the U.S. Department of Energy indicates that upgrading to high-efficiency centrifugal fans can lead to an average annual savings of $1,000 to $4,000 per unit in energy costs, depending on the size and usage of the system. Additionally, these fans often come with longer lifespan and reduced maintenance requirements, further driving down overall costs. By integrating centrifugal exhaust fans into ventilation systems, businesses can enjoy improved air quality and operational efficiency while achieving significant economic benefits.

| Dimension | Data |

|---|---|

| Energy Efficiency Rating | 85% - 95% |

| Typical Power Consumption | 150 - 750 Watts |

| Average Lifespan | 10 - 15 years |

| Noise Level | 45 - 70 dB |

| Common Applications | Industrial, Commercial Kitchens, Warehouses |

| Cost Savings Potential | Up to 30% on energy bills |

To ensure the longevity and efficient operation of centrifugal exhaust fans, regular maintenance practices must be a priority for facility managers. First and foremost, routine inspection is crucial; checking for accumulated dirt and debris on fan blades and housing can prevent operational inefficiencies and airflow restrictions. Cleaning these components not only improves performance but also extends the life of the motor by reducing strain during operation.

Additionally, lubrication of moving parts is essential. Bearings and motors should be greased according to the manufacturer's specifications to minimize friction and heat buildup, which can lead to premature wear. Monitoring noise levels can also be an indicator of performance issues; unusual sounds may signal the need for immediate attention. Furthermore, keeping an eye on electrical connections and ensuring that wiring is intact can prevent unexpected failures, making a proactive approach in fan maintenance vital for prolonged service life and reliability.

This chart illustrates the performance metrics of centrifugal exhaust fans, showcasing their energy efficiency, noise level, maintenance frequency, and airflow capacity. These metrics highlight the advantages of using such fans in modern ventilation systems.