In the realm of modern industrial applications, the significance of centrifugal blowers cannot be overstated. These devices play a vital role in various processes, ranging from material handling to HVAC systems, making them indispensable in today's manufacturing and production environments. According to Dr. Emily Carter, a leading expert in the field of fluid dynamics, "Centrifugal blowers are essential for ensuring optimal air flow and pressure, which are critical for maintaining efficiency and operational productivity in industrial settings." This underscores the growing reliance on centrifugal blowers as industries evolve to meet increasing demands for efficiency and functionality.

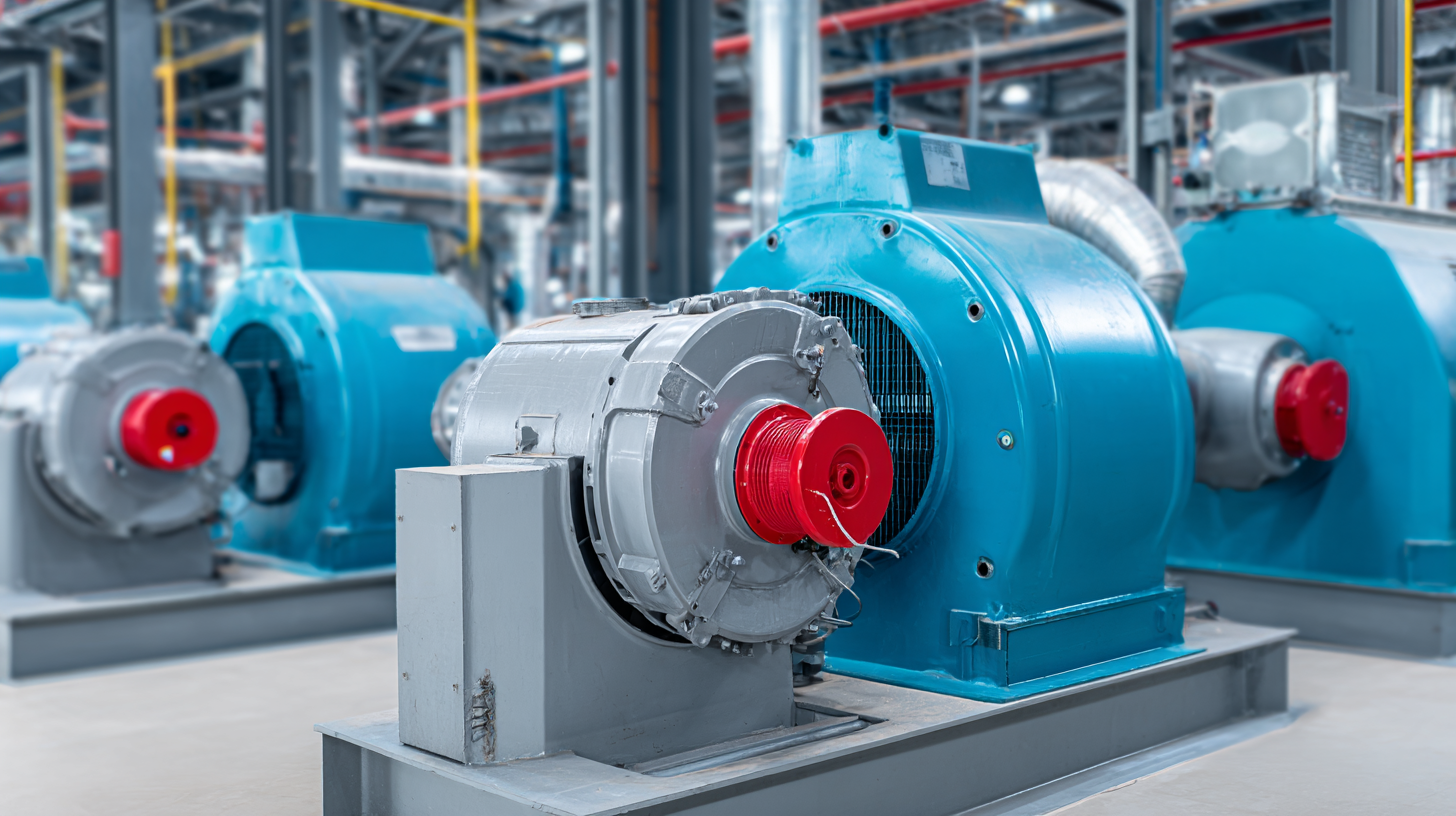

The advancements in technology have further enhanced the performance of centrifugal blowers, allowing for more precise control over air movement and energy consumption. As industries strive for sustainability and reduced operational costs, the integration of modern centrifugal blowers offers unmatched benefits, including high energy efficiency and reduced noise levels. This introduction to the pivotal role that centrifugal blowers play in contemporary industrial practices sets the stage for a deeper exploration of their applications, benefits, and future trends in technology that continue to shape the industry landscape.

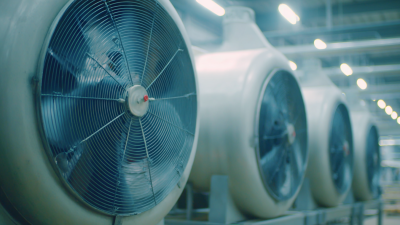

Centrifugal blowers play a critical role in various industrial applications, providing reliable air movement and pressure generation necessary for optimal system performance. Understanding the fundamentals of how these devices operate is essential for engineers and technicians. These blowers utilize a rotating impeller to draw air in at the center and expel it at a higher pressure through a discharge outlet. The design allows for efficient air handling, making them suitable for environments that require steady airflow, such as manufacturing processes, waste treatment facilities, and HVAC systems.

Centrifugal blowers play a critical role in various industrial applications, providing reliable air movement and pressure generation necessary for optimal system performance. Understanding the fundamentals of how these devices operate is essential for engineers and technicians. These blowers utilize a rotating impeller to draw air in at the center and expel it at a higher pressure through a discharge outlet. The design allows for efficient air handling, making them suitable for environments that require steady airflow, such as manufacturing processes, waste treatment facilities, and HVAC systems.

In addition to their basic operation, centrifugal blowers are characterized by their ability to handle large volumes of air at relatively high pressures. This capability makes them ideal for tasks such as pneumatic conveying, where materials are transported through a pipeline using air pressure. Moreover, their design can be tailored to accommodate specific industrial needs, such as varying fan speeds and pressures, enabling customized solutions for different applications. Understanding these fundamentals is vital for ensuring the correct selection and maintenance of centrifugal blowers, ultimately contributing to improved operational efficiency and reduced downtime in industrial settings.

Centrifugal blowers play a pivotal role in various industrial applications, particularly in ventilation, material handling, and cooling systems. When evaluating the efficiency of these blowers, it's crucial to consider key performance metrics such as airflow, static pressure, and power consumption. Airflow, measured in cubic feet per minute (CFM), indicates the volume of air moved, while static pressure reflects the blower’s capability to overcome resistance in the system. Monitoring these metrics helps in optimizing the blower's performance, ensuring it operates within the desired specifications for maximum efficiency.

Tips: Regularly check for any blockages in the ductwork or filters, as these can significantly impact airflow and static pressure. Also, ensure that the blower is appropriately sized for the application to prevent energy wastage and wear on the equipment.

Another critical metric to assess is the blower's efficiency rating, commonly expressed as the ratio of useful power output to total power input. A higher efficiency rating translates to lower operational costs and reduced environmental impact. Maintenance practices such as lubricating bearings and inspecting impellers can enhance efficiency over time and prolong the life of the blower.

Tips: Implementing a routine maintenance schedule can prevent unexpected downtime and keep performance metrics within optimal ranges, ensuring a smooth operation for all industrial processes relying on centrifugal blowers.

Centrifugal blowers play a vital role in numerous industrial applications, providing efficient airflow solutions across various sectors. One of the most prominent areas of application is in the wastewater treatment industry, where these blowers supply the necessary aeration for biological processes. Their ability to deliver high volumes of air at relatively low pressures makes them ideal for maintaining optimal conditions in treatment tanks.

In the manufacturing sector, centrifugal blowers are extensively used for material handling. Whether it’s transporting bulk powders or granules, these blowers ensure smooth and continuous flow, significantly improving productivity. Additionally, they are commonly found in HVAC systems, where they help regulate air circulation, enhancing the overall comfort and safety of the environment.

Tips: When selecting a centrifugal blower for your application, consider factors such as airflow requirements, energy efficiency, and noise levels. Regular maintenance is also crucial; keeping the blower clean and well-lubricated can extend its lifespan and ensure high performance. Lastly, ensure that the blower is appropriately matched to its application to avoid operational issues.

Centrifugal blowers and positive displacement blowers are both essential tools in various industrial applications, each offering distinct advantages. Centrifugal blowers operate by converting rotational kinetic energy into potential energy, allowing them to generate high volumes of air at lower pressures. This makes them ideal for applications such as ventilation, dust control, and material handling. In comparison, positive displacement blowers work by trapping a fixed volume of gas and forcing it out, providing a more consistent flow at higher pressures. This characteristic is particularly beneficial for applications requiring precise air or gas flow, such as pneumatic conveying systems.

When choosing between these two types of blowers, consider the specific requirements of your application. Centrifugal blowers are generally more efficient at moving large volumes of air, while positive displacement blowers excel in situations where maintaining pressure is crucial.

**Tips:** Before making a decision, assess your system’s pressure and flow needs carefully. Additionally, look for energy efficiency ratings, as this can significantly impact long-term operational costs. Regular maintenance is crucial; ensure that the blowers are serviced to avoid unexpected downtimes and to prolong their operational life.

| Feature | Centrifugal Blowers | Positive Displacement Blowers |

|---|---|---|

| Operating Principle | Air is drawn in and accelerated through a rotating impeller, creating high velocity output. | Air is trapped in a chamber and displaced by the movement of positive displacement rotors. |

| Applications | Used in HVAC systems, dust collection, and material handling. | Common in pneumatic conveying, wastewater treatment, and air flotation. |

| Efficiency | More efficient at higher air volumes and pressures. | More efficient at lower air flows and specific pressures. |

| Noise Level | Generally quieter due to smooth airflow. | Tends to be noisier due to the mechanical action of displacement. |

| Maintenance | Requires periodic cleaning and inspection of impeller. | Focus on lubrication and wear of the rotors and seals. |

| Cost | Generally lower initial cost for equivalent capacities. | Potentially higher initial investment, but can offer long-term savings. |

The future of centrifugal blower technology is poised for significant advancements driven by the evolving needs of various industries. With the increasing demand for energy-efficient solutions, manufacturers are innovating designs that minimize power consumption while maximizing airflow and pressure capabilities. The integration of smart technologies, such as IoT connectivity, is also on the rise, enabling predictive maintenance and real-time monitoring which enhances operational efficiency and reduces downtime.

Market growth for centrifugal blowers is expected to accelerate due to the expanding applications across sectors like wastewater treatment, food processing, and HVAC systems. As industries seek sustainable practices, there is a growing emphasis on eco-friendly materials and designs that reduce environmental impact. Furthermore, the adaptation of centrifugal blowers in emerging markets, driven by urbanization and industrialization, presents new opportunities for innovation and expansion, ensuring these systems remain a vital component of modern industrial processes.